The concept of Value Engineering (VE) first emerged during World War II when companies faced material shortages and needed to find ways to maximize the utility of their resources. Aimed at improving the value of a product or service without compromising quality or performance, this structured approach is still widely used across the AEC industry. Cuono Engineering offers Value Engineering services to many of our clients. By examining the functions and identifying unnecessary costs, we are able to offer more significant cost savings, while maintaining (and sometimes even enhancing) the structural design, integrity, and details of the overall project.

Cuono Engineering is currently providing Value Engineering services for The Village of Mamaroneck. Last year, we were contracted for the structural design of the Parks Department’s Sign Shop Facility and the adjacent site retaining walls. The new building would replace the existing outdated structure on the site at Memorial Park in Larchmont. Lewis + Lewis Architects designed the concept for the new 3,200 square foot, 2-story which also featured a loft and lower-level garage. Due to all of the bids coming in over the project's initial $2 million budget, the lowest bid being around $2.7 million, a review and discussion was initiated with the town board for the redesign of the building that not only kept the budget in mind, but maintained the original look and spirit of the building.

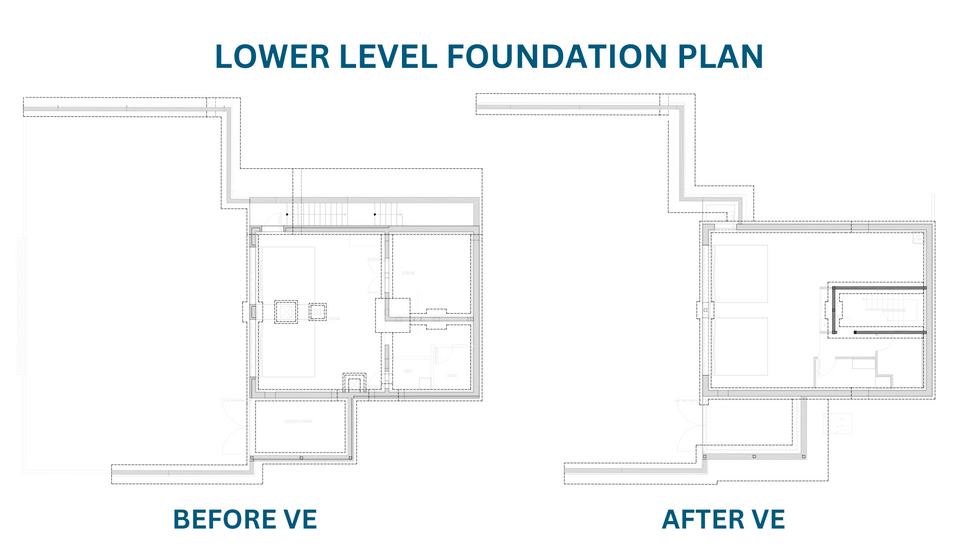

Cuono Engineering's proposed redesign removed the exterior stairs and the associated concrete retaining walls and footings but relocated them to the interior of the building which still allowed direct access from the lower level to the upper level. At the upper level covered entry, we squared off the building which allowed the elimination of several steel beams and the concrete on metal deck. We also removed the exterior stone veneer and cantilevered upper-level framing which ultimately simplified the concrete work and reduced framing member sizes. At the roof, we lowered the pitch, reduced the extensive overhangs, and replaced the 8 individual dormers with 2 central dormers which significantly simplified the roof framing. We also replaced the interior stair up to the loft storage level with an attic pull-down stair to a mechanical level attic space.

The footprint of the building and overall function didn’t change, and the exterior aesthetics of the building were respected as best as possible. With the many small but effective revisions that were made, there is anticipated to be a huge cost savings for the town. Although some interior space was sacrificed by moving the exterior stairs to the inside of the building and converting the storage loft to a mechanical attic level, the overall functionality of the building was preserved. By strategically locating the indoor stair in such a way that the floor spans could be reduced, a reduction in more expensive engineered lumber was achieved. Also, by converting the loft storage to a mechanical attic, the floor loading criteria was significantly reduced and member sizes at that level and the levels below were optimized.

Value engineering for this project began at a very desirable time - after the bids came back, yet before the construction contract was awarded. This allowed for more time spent brainstorming ideas to reduce cost, nullifying any significant design challenges. We were able to simplify the structure with minimal sacrifice of aesthetics and functionality to the building.

While Value Engineering can be applied at any stage of a project's lifecycle, it’s particularly beneficial during the Design and Pre-Construction Phases. Early collaboration during the Design Phase allows for us to comprehensively evaluate design alternatives with the architect and other design team members. Even during Pre-Construction, VE can identify cost-effective construction methods before the construction team is mobilized and significant investments are made.

The VE process typically follows a structured five-phase approach.

1. Information Phase

During this time, we gather information about the project to understand its purpose, functions, and current costs. This phase is particularly important to third-party consultants who have been hired to participate in the value engineering process.

2. Function Analysis Phase

We then can identify the essential functions of the project and classify them as either necessary or desirable.

3. Creative Phase

Next, we brainstorm potential alternatives that achieve the same necessary functions with less cost or better quality. This can include modifying materials, applying different technologies, or changing design approaches.

4. Evaluation Phase

This allows us to assess the proposed alternatives based on criteria such as feasibility, cost, and impact on functionality. A functional cost analysis may assist in determining which alternatives add the most value.

5. Development Phase

Finally, we select the best alternatives and develop them into workable solutions. This often involves preparing detailed designs and plans and assessing implementation challenges.

With many advantages, Value Engineering should always be considered as early as possible to avoid any potential challenges, including time constraints. If not incorporated early in the project, VE efforts can unfortunately be sidelined due to tight timelines. When planning for your next project, be sure to discuss the options of Value Engineering with us!

Comments